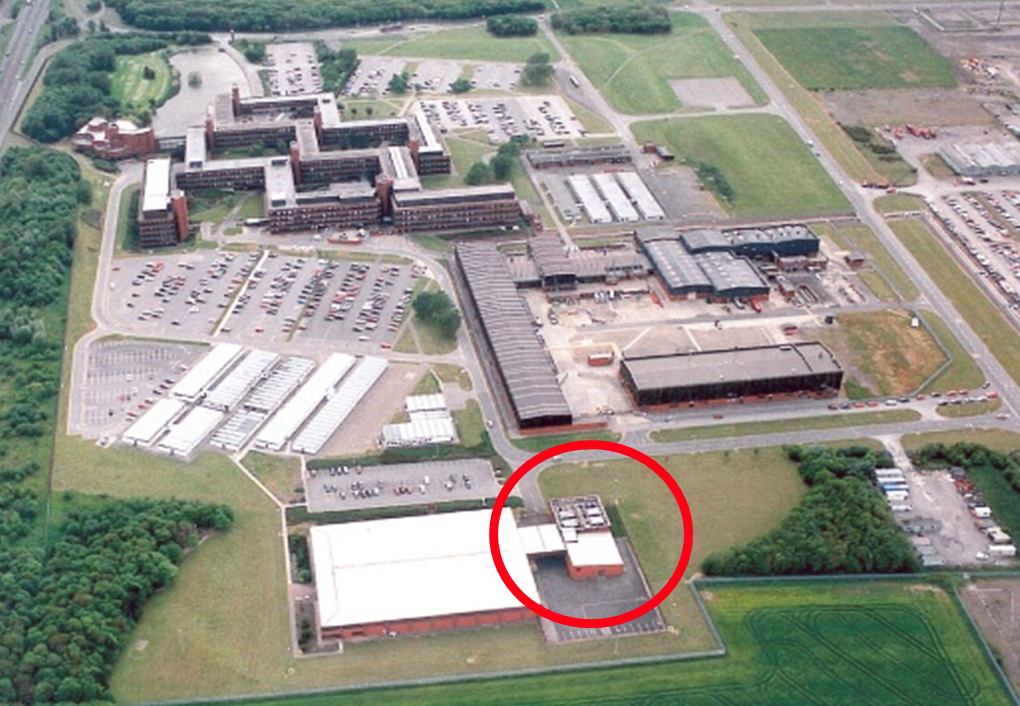

In July 2008 CompactGTL’s first pilot plant was successfully commissioned at Wilton, in North East England, demonstrating the fully integrated CGTL process for the first time. The test facility at Wilton enabled the full evaluation and development of the process operating ‘envelope’ as well as the start-up, shut-down and normal operating procedures. The 24 hours a day facility operated continuously for over six years. The Wilton facility also provided a valuable test bed to evaluate pilot scale SMR and FT reactors and catalysts supplied by candidate equipment manufacturers during the earlier stages of the development programme.

The plant, which incorporated CGTL’s proprietary SMR and FT technology, was constructed to demonstrate the fully integrated process operating under commercial conditions. Throughput is 1 bbl of synthetic crude per week and the feedstock can be controlled to test the variety of associated gas compositions encountered. Testing at this scale provided valuable operability data that fed into the larger scale demonstration plant and commercial plant projects.

Using advanced development and testing facilities both in the UK and at Bayer Technology Services in Leverkusen, Germany, CGTL has established an extensive operating track record for its FT reactors and catalysts, achieving over 40,000 hours of pilot and demonstration scale operation in addition to more than 290,000 hours of laboratory testing.