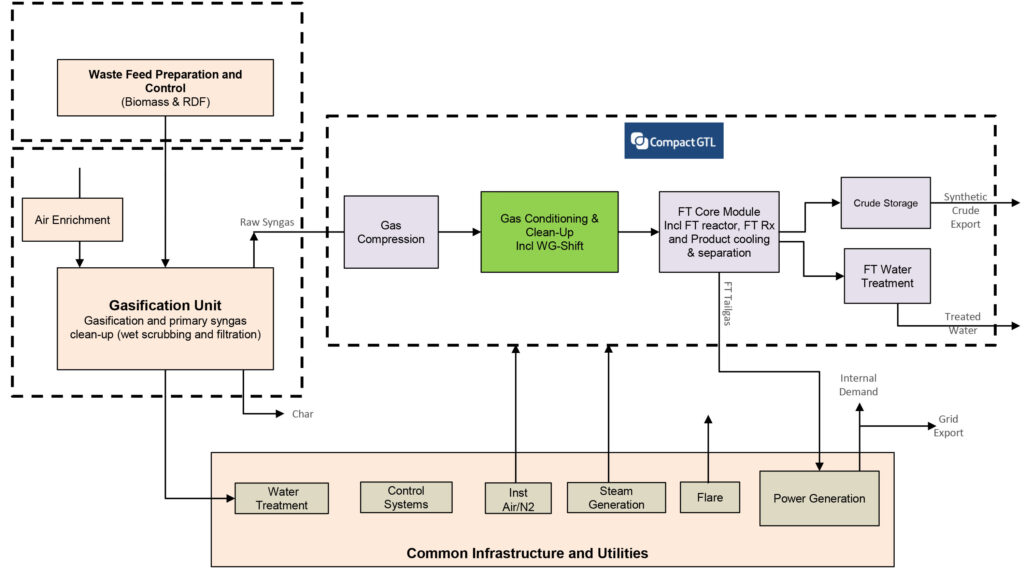

CGTL has been designing an integrated small-scale modular waste-to-sustainable fuel facility. The facility will integrate three different technologies: downdraught gasification (through gasification partner company), synthesis gas clean-up, and a Fischer Tropsch unit for production of a synthetic crude that can be upgraded to drop-in sustainable drop-in liquid fuel for the aviation and heavy haul industries that have limited scope for decarbonisation and electrification. The final products include Sustainable Aviation Fuel (SAF), diesel, naphtha and, optionally hydrogen.

This small-scale modular plant covering the full value chain, from waste in to liquid products out, is implemented as a series of standardised skid/modules that are easy to transport and set up at existing local waste management facilities with capacity ranging from 100 to 500 tons per day.

Advantages of CGTL small-scale modular FT based WTL plants at local waste management facilities would include:

- Better and more consistent quality of feedstock.

- Standardised and modular design resulting in lower engineering and capital cost while enabling short project delivery schedules.

- Removal the need for large scale transport of waste of long distances.

- Low financial hurdles to overcome for small scale facilities.